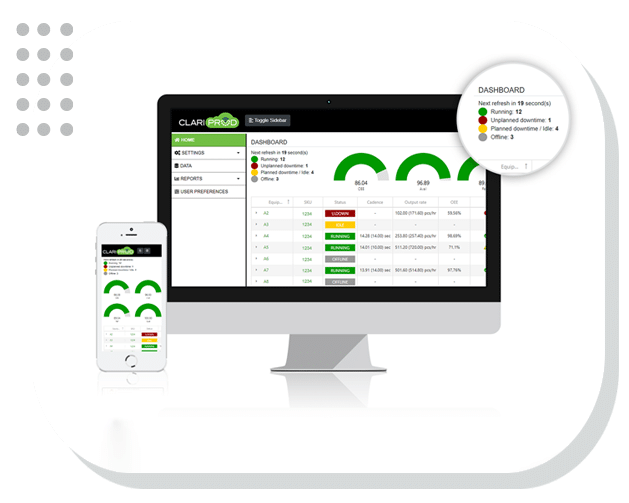

Plug & Play real-time production monitoring system for the plastics industry

Real-time production monitoring system to increase productivity

Producing better and faster is now a must to stay competitive in manufacturing. This starts with getting insights from your operations, mostly your machines.

REDUCE DOWNTIMES

INCREASE THROUGHPUT

ELIMINATE REJECTS

OPTIMIZE SLOW-RUNNING MACHINES

The CLARIPROD manufacturing monitoring system includes a smart controller to collect data from your machines, and a portal with business intelligence to deliver data-driven insights. Take action now to increase your productivity !

The CLARIPROD manufacturing monitoring system includes a smart controller to collect data from your machines, and a portal with business intelligence to deliver data-driven insights. Take action now to increase your productivity !

Get actionable data after 1 day

After implementing the Clariprod manufacturing monitoring

system, Windmill Plastics saw some outstanding results

43% increase in overall productivity

$150 /machine: monthly savings in reducing downtimes

$2,000 /affected machine: monthly cycle-time savings

Connected Clariprod with their ERP system to exchange data in real-time

These manufacturers trust Clariprod every day to increase their productivity

Quickest ROI in the industry

Calculate your own ROI to see how our manufacturing monitoring system could benefit your business

What makes the Clariprod manufacturing monitoring system unique?

Quick to deploy

Plug & Play, data immediately usable, and scalable system

Made for the plastics industry

Compatible with any injection molding or extrusion machine

Most accessible solution

Low initial setup fees, simple solution, only giving you the information you need

Reach maximum profitability

Increase productivity with the lowest investment for the quickest ROI

To improve your production efficiency

Get our tips on how to help your business