Manufacturing monitoring system for the plastics industry

The Clariprod manufacturing monitoring system

The Clariprod real-time production monitoring system was designed to address the challenges faced by businesses in the plastics industry, such as machine downtimes, quality inconsistency, and slow-running machinery.

The controller delivers real-time production data directly to the cloud-based portal, giving you insights on your production to increase your efficiency.

Components of our manufacturing monitoring system

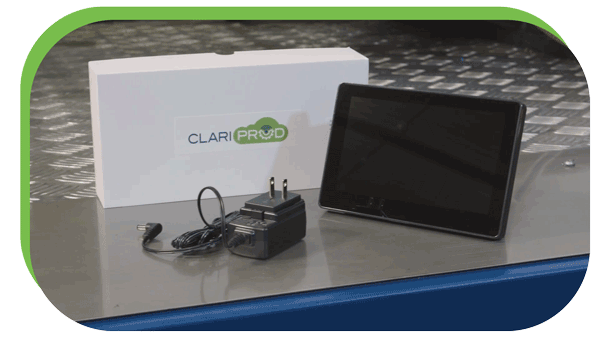

Our Plug & Play system

Plug & Play? What does this mean and why is it an advantage? It’s simple; everything is already programmed into the hardware – your Clariprod controller – when you receive it. Compared to a custom monitoring system, you don’t need an in-house IT structure to integrate it into your factory or even to support the system. There are no additional installation costs either, as it is ready to install when you receive it, and it only takes a few minutes to connect it to your machine. All you must do is configure a few settings already programmed into the hardware, and you’re ready to start collecting data.

This means very low installation costs for you and actionable data from day one! You only pay for the system and service that you get, with no additional fees.

Investing in production monitoring will bring you steady savings by:

Investing in production monitoring will bring you steady savings by:

Real-time production monitoring is the answer to your daily questions

Keeping track of everything in the factory can be hard sometimes, and this is why real-time monitoring can help you save money, increase productivity and keep your production on track. Clariprod allows you to set alerts so you can be made aware of costly manufacturing problems, allowing you to quickly direct your resources to address these issues and therefore saving precious time.

Real-time production monitoring is the answer to your daily questions

Keeping track of everything in the factory can be hard sometimes, and this is why real-time monitoring can help you save money, increase productivity and keep your production on track. Clariprod allows you to set alerts so you can be made aware of costly manufacturing problems, allowing you to quickly direct your resources to address these issues and therefore saving precious time.

If these are frequent questions in your factory, we have the solution for you:

Book a free demo to learn more about our solution

We are so convinced of our solution, that we will refund you if it doesn’t fit your needs!