Improve your OEE with real-time production monitoring

The Clariprod Portal provides you analytics with detailed metrics, historically and in real-time, to measure your key performance indicators (KPI) to improve your OEE and your efficiency.

The Clariprod Portal provides you analytics with detailed metrics, historically and in real-time, to measure your key performance indicators (KPI) to improve your OEE and your efficiency.

How to improve your OEE (Overall Equipment Effectiveness) ?

OEE is a well-known indicator to measure your overall production efficiency by monitoring your equipment performance. This indicator can help you identify potential problems and indicate ways to improve your productivity, by tracking important KPIs like availability, performance, and quality.

Being aware of manufacturing problems such as downtimes, slow-running machines, and inconsistent quality, enables you to take action to fix them quickly, and this is how you can improve your OEE and your overall efficiency.

Improving your OEE by understanding it

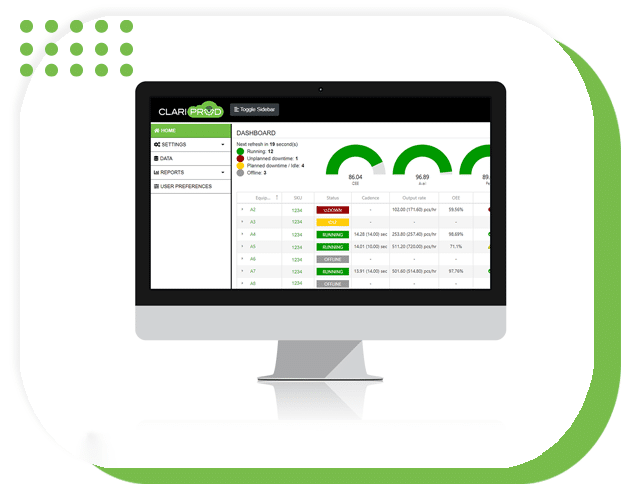

Clariprod calculates your real-time OEE in a dynamic dashboard with data on your availability, performance and, quality. Here is how this indicator is calculated:

OEE = Availability x Performance x Quality

View OEE improvement results in real-time

Availability, performance and quality have a direct effect on your overall equipment effectiveness. The Clariprod Controller tracks these KPIs in real-time to provide you an up-to-date OEE at all times, so you can always be aware of your productivity. You can also compare your current production with historical data to track improvements easily.

View OEE improvement results in real-time

Availability, performance and quality have a direct effect on your overall equipment effectiveness. The Clariprod Controller tracks these KPIs in real-time to provide you an up-to-date OEE at all times, so you can always be aware of your productivity. You can also compare your current production with historical data to track improvements easily.

Improve other KPIs

with Clariprod

with Clariprod

Clariprod also allows you to track multiple other critical KPIs to increase your productivity :

Improve other KPIs

with Clariprod

with Clariprod

Clariprod also allows you to track multiple other critical KPIs to increase your productivity :