“Simplicity is the ultimate sophistication” ̶ Leonardo Da Vinci

Things become clearer when they are simple. Similarly, simplified data tracking gives a clearer picture than overly complex data.

In manufacturing, production monitoring is the exercise of continuous control of the production process and machines. Undertaking this monitoring is necessary to obtain a real-time status, assure continuous improvement, and avoid downtime.

There are different monitoring systems on the market. Each of them has its own benefits and uses. Even though one of the main advantages of a monitoring system is production improvement, we all want a better return on investment (ROI) at the end.

First, we’ll review the variables that monitoring systems provide. Then, we’ll explain why it’s important to simplify and focus on the data that’s needed to increase revenue.

Parameters of Production and Machinery Monitoring:

A production monitoring system measures various parameters to provide real-time information on the status of the production and its machines. The parameters that the production monitoring system measures are as follows:

Cycle Time: This is the time taken by a machine to manufacture a unit from start to finish, before starting another unit. [1] It tells manufacturers whether the machine is working at the optimal rate or not. Optimizing the cycle time directly increases productivity.

Throughput: This indicates the overall production of the plant in a specific period. Measuring it allows manufacturers to know if the production rate is as desired, or if they are experiencing losses due to slow machine production or downtime.

Reject Ratio: This allows the manufacturer to measure produced scrap. This parameter is calculated to reduce waste production as much as possible to reach the profitability goal.

Count rate: This parameter counts the number of units produced in a selected period. It is calculated to increase the throughput and check whether the desired target is reached or not.

Downtime: This calculates how long the production of a machine has been stopped and why. Downtime could be due to several reasons, such as a planned maintenance stop or an unplanned breakdown. The main objective is to reduce downtime to ensure the smooth operation of the plant. The less unplanned downtime there is, the more production and profit the manufacturer makes.

Overall Equipment Effectiveness (OEE): This measures whether all the resources of the plant are used to the desired value. This calculation ensures that the plant runs smoothly and uninterrupted in order to achieve maximum efficiency and profit.

All these metrics have a direct effect on revenue and profit, which is why they are so powerful. Other monitoring systems calculate even more metrics than the main ones mentioned above, such as on-time delivery, on-schedule production, planned maintenance percentage (PMP), customer return rate, etc.

But is it useful and cost-effective to know all that?

Why is Focusing on main Parameters important?

Maximum efficiency is achieved when work is done in its simplest form. When you work simply, you can focus more on the objective and the work to be done. The same is true for a production monitoring system. Although it is fully digital and calculates all the parameters with equal efficiency, the decrease in performance is seen when it comes to analyzing all this data and translating it into actions.

Speed is always affected when processing large amounts of data. This makes it difficult for workers to separate the necessary data from the less critical data. This can dilute improvement efforts and slow down problem mitigation. Therefore, key performance indicators (KPIs) or metrics must be simple and accurate.

The simpler the data, the simpler and clearer appear the actions needed to solve problems or increase productivity. This is where the quick return on investment comes from.

Choose Simplified Data for a Quick Return on Investment

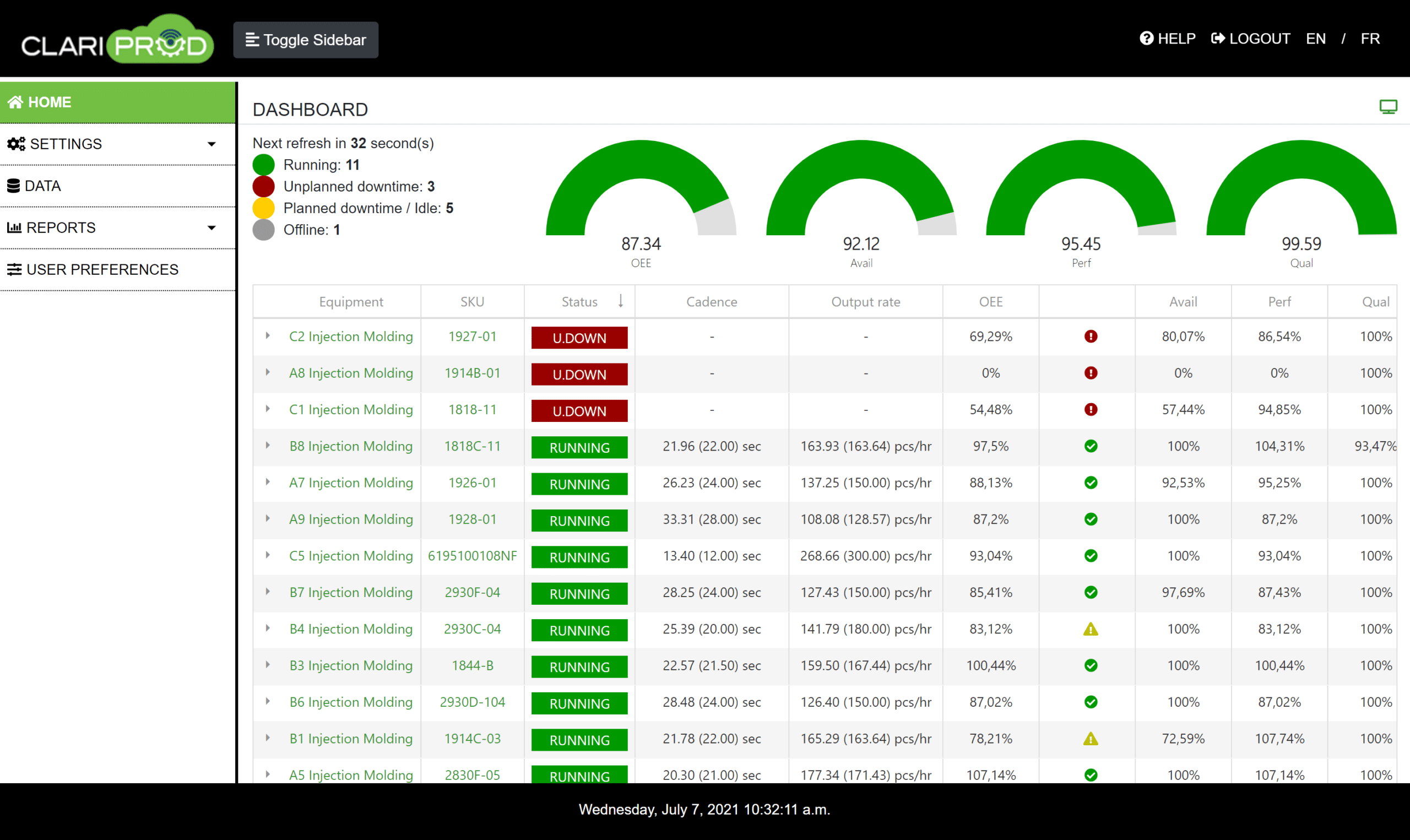

One of the best options is Clariprod. Clariprod is a monitoring system that provides manufacturers with only the data that is necessary for production optimization. With the simplified and useful data processed by this production monitoring system, you can focus on what really matters, improve your efficiency quickly, and leverage your investment with simple and cost-effective actions.

Return on investment is an important metric for any manufacturer who wants to make a high profit. There is no point in investing in something that will take years to recoup. Therefore, manufacturers need to invest in production monitoring systems that are necessary for their plants. The production monitoring system must select the essential data to manage production and make profits, so that money and time are not wasted, and unnecessary time-consuming calculations are avoided.