Almost every manufacturing environment relies on current or historical production data to operate. The usage of this data allows manufacturers to make decisions that account for budgets, cost-effectiveness, OEE, etc. Without utilizing this info, a company can see tremendous losses since there may be improvements or errors not being noticed. Therefore, easily acquiring and analyzing production data is essential throughout the manufacturing process. By integrating Production Monitoring and using Display Boards, full visibility of shop floor productions is possible. Centralization allows for easy access and analytics of important data.

Visible Shop Floor Metrics

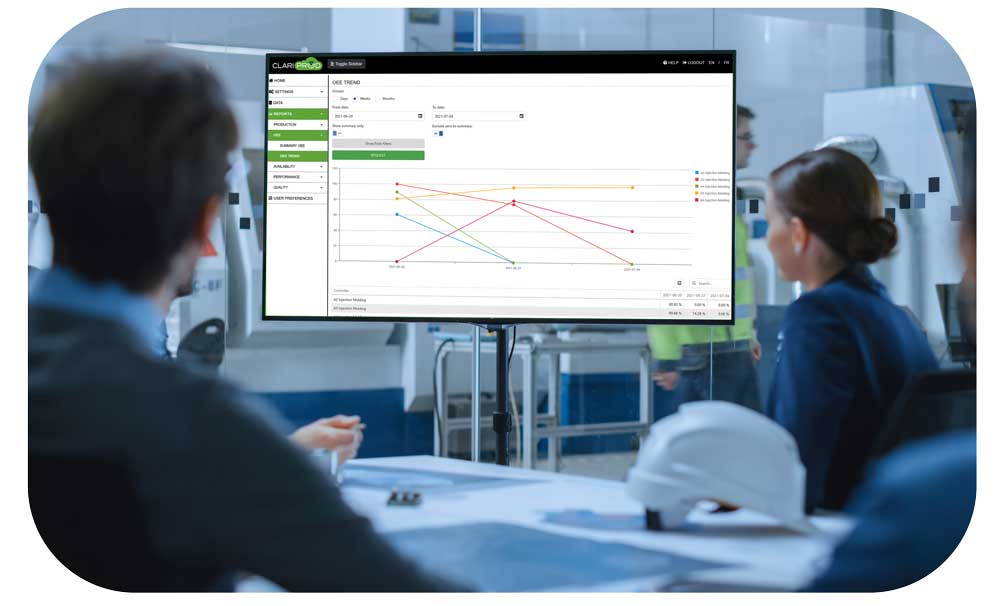

At each machine, Clariprod (using an installed controller) displays relevant information specific to the process being conducted there. This information includes but is not limited to: cycle times, rejects, remaining time, remaining quantity, work orders, rates (target and current), etc. All information is then wirelessly gathered and stored on a central portal. This portal can be accessed on any device and can also be viewed directly in the workshop, for example on a TV or cell phone. Depending on the configured settings, it will display certain data analytics from the entire operation (while still having the capability to show individual machine info). This involves important aspects such as live OEE, the status of each machine, quality score, machine downtimes, ability performance/score, etc.

Benefits of Production Display Boards

All the listed information above is crucial to developing an understanding of day-to-day production. By utilizing display boards on each machine and central hubs, manufacturers are subject to numerous benefits:

Display of Production

Since all useful information and data are on a visible display screen, it is easy to access and understand this data from any point on a shop floor. This is especially useful for any employee who needs production information quickly to perform their duties, by having a visual of the overall productivity of each machine and of the whole production. A visual display of production efficiency and dashboards makes it possible to notice immediately any possible improvements or corrections to stay on track or to improve processes.

Better Decisions

Due to the centralization of all production data, decision-making is easier and faster. By supplying manufacturers with facts about their shop floor, analytics can be thorough and accurate.

Global Visibility

Factory-wide visibility allows manufacturers to have full control of their operations without the need to address each machine individually. Overall productivity and effectiveness can be determined easily, and improvements or adjustments can be made appropriately.

Real-Time Information

By utilizing display boards, manufacturers can receive real-time data on production procedures. This will give much-needed insight by displaying current machine performance and criteria like rate of production. Unexpected downtimes can also be noticed with ease, and cellular alerts are also available to selected personnel.

Improved Communication

Since a display board can show department as well as factory-wide metrics, communication is greatly increased. Adjustments or actions can be planned based on the displayed information. This could involve employees identifying bottlenecks and taking corrective action or be as simple as a quick checkup to ensure processes are running smoothly.

Conclusion

To summarize, production monitoring is essential if manufacturers want an efficient way to gather and analyze data. The use of Production Display Boards also offers many benefits that maximize efficiency by displaying current production and important key performance indicators directly on the shop floor. Clariprod provides efficient production line monitoring for any manufacturing environment and automates data collection which allows for data centralization. Clariprod products come equipped with production display boards for each machine and can easily be connected to more screens to display global data and analytics directly on the shop floor. If you have any questions, feel free to contact us or visit our website: https://clariprod.com/.